Generic Information

The equipment is responding to the normative of Directive 2006/42/CE (EU OSHA);

Any other certifications of conformity could be discussed during negotiations;

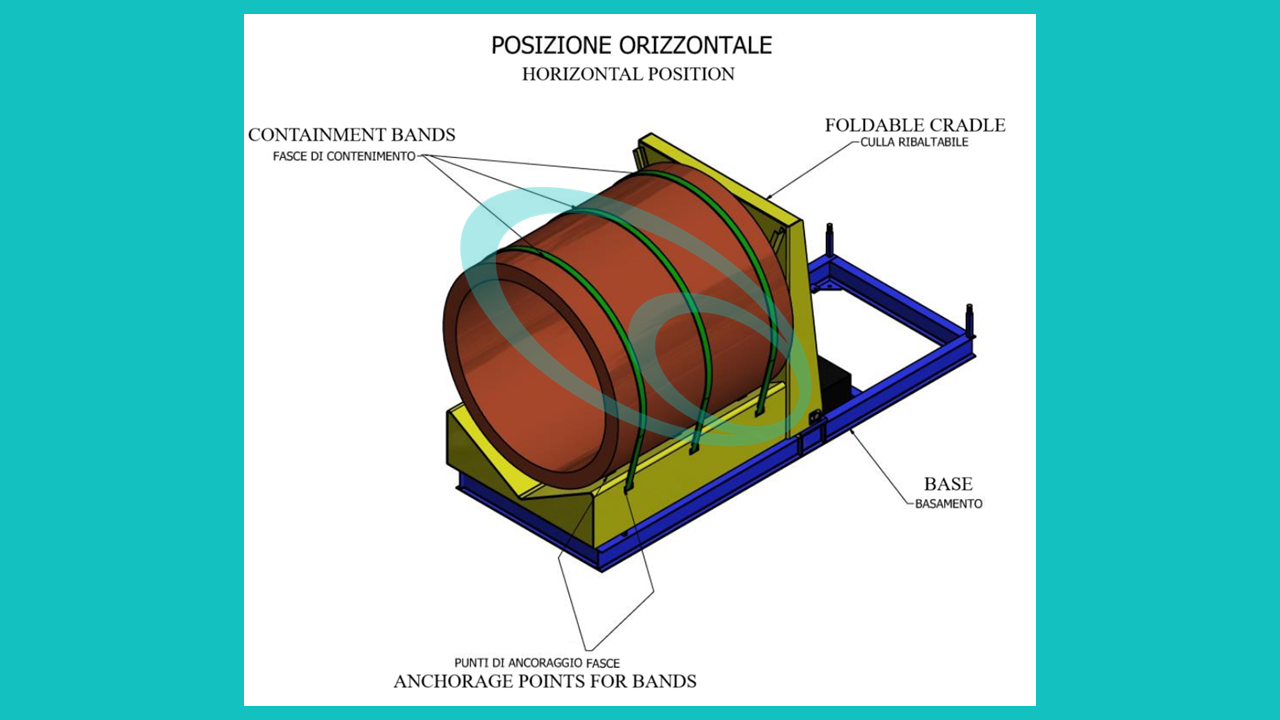

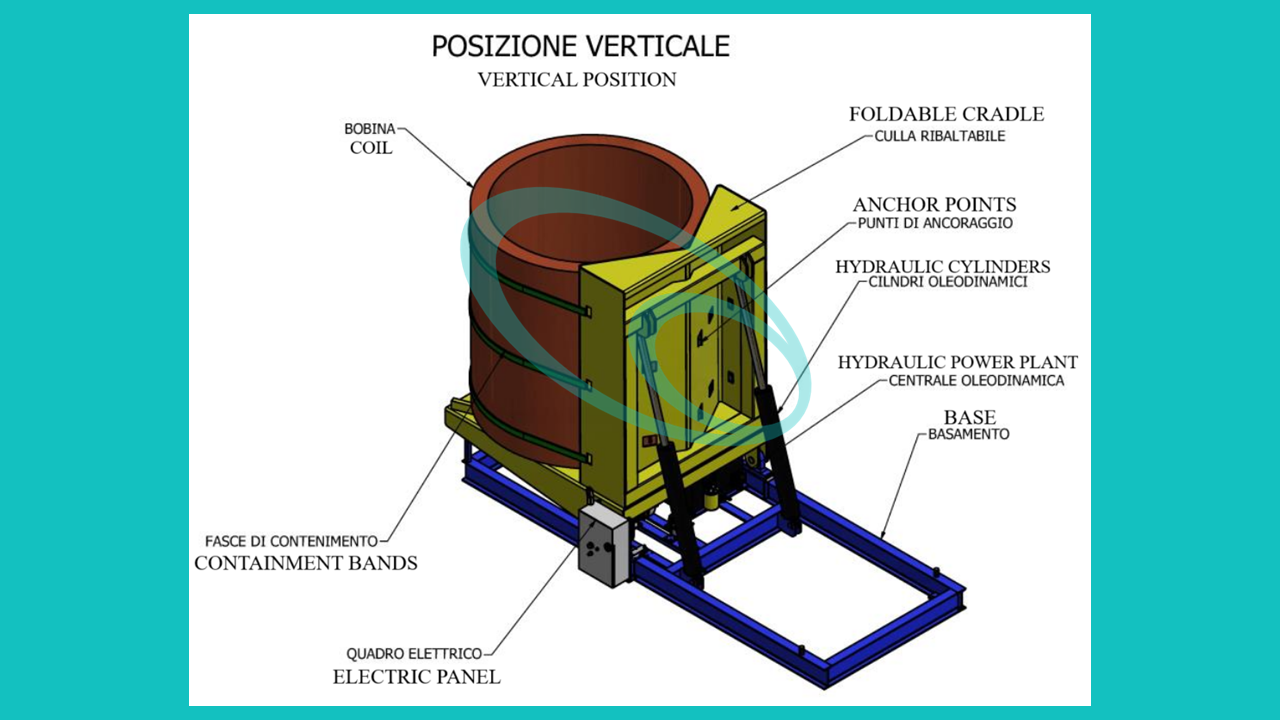

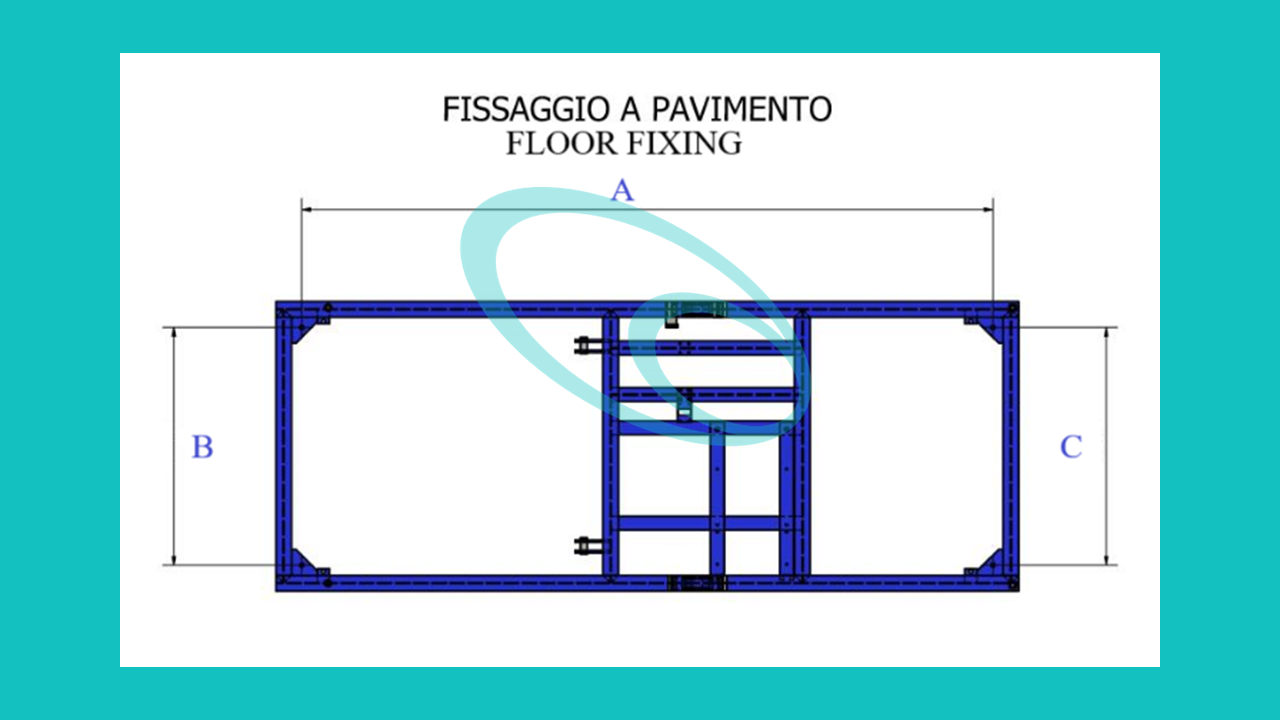

The equipment can be constructed based on the customers requested dimensions;

The equipment can have any RAL color based on the customers requirements;

Manual of Use: both in English language and requested additional language;

Warranty: for EU countries is 24 months, for others 12 months;

Delivery: Depends on busyness of the factory, normally around 180 working days after PO;

Payment terms: preferred is 50% bank transfer against P.O. + 50% bank transfer at delivery time EXW;

Factory Acceptance Test (if necessary) – in-person or video-call;

Power Requirements: Standard – 380V/3 phase/50Hz. For USA – 480V/3 phase/60Hz;

Temperature & Humidity: 10°C-40°C (50°F-100°F) and 20-80% RH;

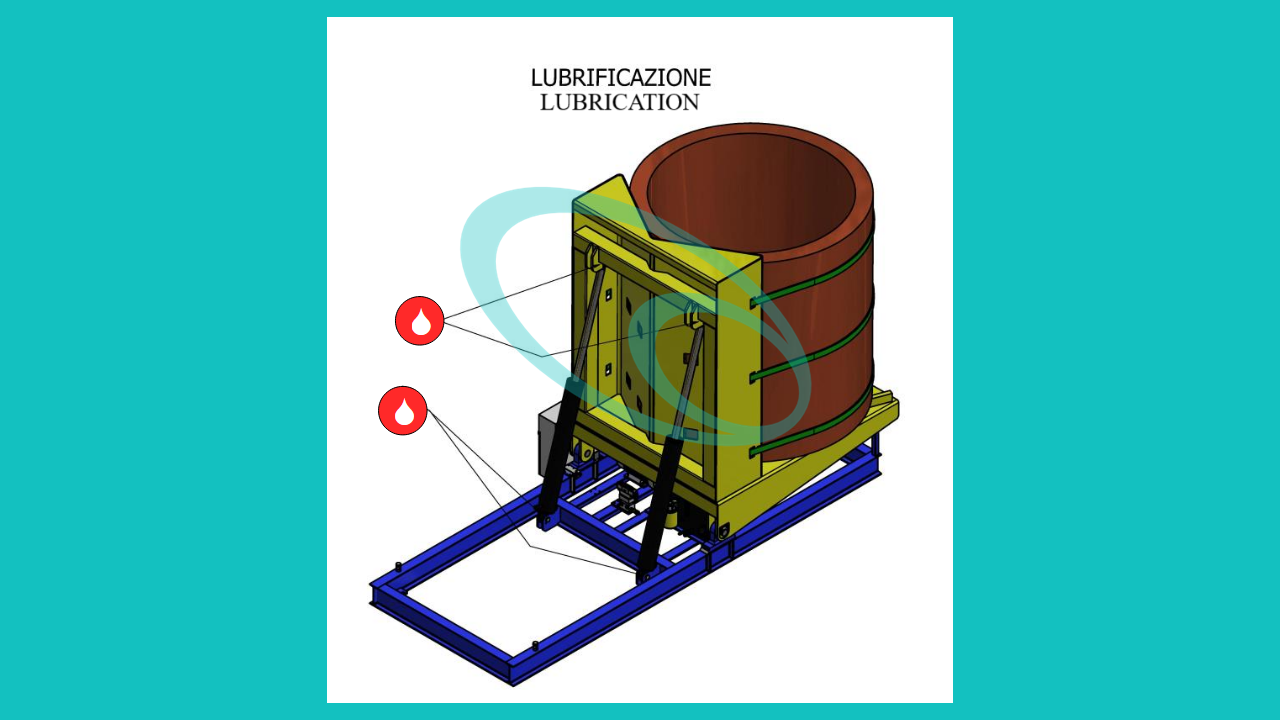

Corrosion Protection: Coated or corrosion-resistant material;

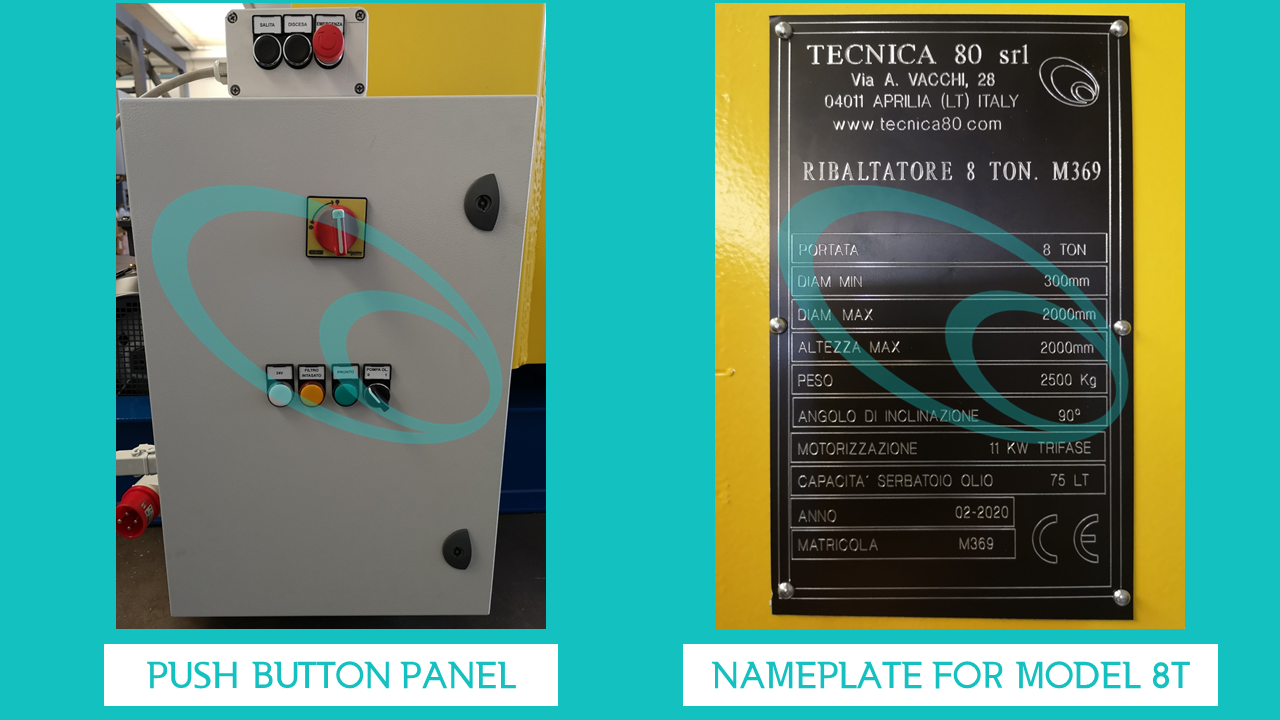

Control System: Remotely with push-button panel.